Denray Machine Inc. Presents

I Love My Job, I Love The People,

I HATE THE DUST!

What Is Dust?

Dust is a small particle that has been removed from a larger substance. It has been removed by high-speed cutters, or removed by abrasives. Cutters will produce big and small particles, where abrasives will produce mostly small particles. Big particles are considered to be between 2.5 and 10 microns in size, where small particles are 2.5 microns and smaller. 2.0 microns are 50 times smaller than a typical human hair.

Are all dust particles harmful? NO, depending on their size. Some types of dust may not be harmful to your health, but may be small enough that your body can’t rid itself of the inhaled dust.

This may become an issue because small amounts of this dust you breathe in can’t leave your body through the respiratory system, so it either stays in the lungs or is transferred into the blood stream, filtered out in you liver, and may or may not be harmful to you.

Dust is a small particle that has been removed from a larger substance. It has been removed by high-speed cutters, or removed by abrasives. Cutters will produce big and small particles, where abrasives will produce mostly small particles. Big particles are considered to be between 2.5 and 10 microns in size, where small particles are 2.5 microns and smaller. 2.0 microns are 50 times smaller than a typical human hair.

Are all dust particles harmful? NO, depending on their size. Some types of dust may not be harmful to your health, but may be small enough that your body can’t rid itself of the inhaled dust.

This may become an issue because small amounts of this dust you breathe in can’t leave your body through the respiratory system, so it either stays in the lungs or is transferred into the blood stream, filtered out in you liver, and may or may not be harmful to you.

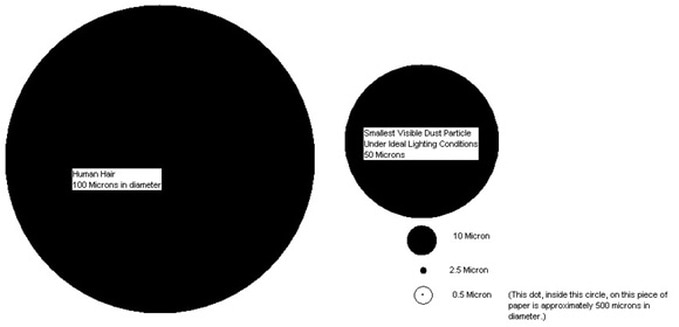

The above diagram will give you a comparison that the average person can really relate to. Everything is made much larger so you can visually see the comparison. The big dot represents the cross section of an average human hair or approximately 100 microns in diameter. The next dot represents the smallest dust particle that can be seen with the naked eye under ideal lighting conditions such as a beam of sunlight shining through a window. The smallest dust particle that you can see floating in that beam of light is approximately 50 microns in diameter.

Dust particles that are 10 microns in diameter and larger are considered to be large enough to either be caught in the nasal passages, or brought back up out of the upper lungs by cilia. (Cilia are hair like media in the upper lungs and bronchial passages that bring up dust and other foreign matter)

Particles 2.5 micron and smaller are believed to settle in the lower area of the lungs and can’t be brought back up. Once there, they may be dissolved and go into the blood stream to be filtered by the liver, and possibly eliminated from the body. Some of the particles may not be dissolvable and may stay in the lungs, and may cause a variety of problems. (Ex. Allergies, respiratory problems, lung diseases and even cancer). Some of the dust going into the liver may also cause many different medical issues that may or may not be treatable, not to mention incurable.

JUST HOW DUSTY IS YOUR SHOP?

Many of you reading this believe your shop is not all that bad, and some of you may be correct. Some people say we have a serious problem. Those of us in the woodworking industry (including many people reading this) know that OSHA has announced that wood dust is a carcinogen. Many people still debate that ruling and always will. The majority of people that own or operate a shop have little if any idea how much dust is really the maximum limit allowed by OSHA. For most types of wood dust the measurement of 5 mg/m3 is the maximum dust level allowed. Some wood dust has only 3 mg/m3 limits and a few have as low as 1 mg/m3. If you are in the majority, you have no clue what this means.

Some people know that 5 mg/m3 means 5 milligrams of dust per cubic meter. Now some people will say: Just how much is that? NOT MUCH!!! Using flour as a substitute for wood or solid surface dust, I measured out the amount of flour that is the same volume (not weight) as a dime. I weighed the flour in milligrams and converted it to the cubic meter limit allowed by OSHA, 5 mg/m3. If you were to spread the dust evenly into the air and achieve the maximum limits allowed by OSHA, you would need a room 10 ft. x 10 ft. x 8 ft. tall to get a “dime’s worth” of dust to fill the air to the limit. That is at 5 mg/m3.

You say: Who could even see that little amount of dust in normal work environment lights.

You are right: NOW, HOW DUSTY IS YOUR SHOP?

Now, before the panic sets in and a knee-jerk reaction occurs, let’s look at the whole picture. That dust will only be at the maximum level for a few minutes, because it will start to slowly settle below the breathing zone. If more dust is created on an ongoing basis (for instance if someone or several workers were working full time creating dust), then that process and the dust it creates becomes a major concern. The 5 mg/m3 is the maximum limit of full time exposure, so there is some averaging available in these numbers. With spurts of 10 mg/m3 exposure means there needs to be times of basic 0-1 mg/m3 exposure to average at the maximum. (This is known as Time Weighted Averaging, or TWA.)

You may ask: How can we know what our exposure level is? Some work-comp insurance companies will do studies for you, and private safety companies can do testing also. They use a little machine about the size of a big cell phone hooked to your belt all day; this machine will suck air in like a person breathing. At the end of the work period the little monitor will indicate at what level that person was exposed to.

DUST MASK

Are dust masks the answer? Yes, in some cases and NO in most cases. The proper dust mask, and the proper use of them, is 1st: uncomfortable for the person wearing the mask and, 2nd: expensive for the company. In some cases, they are the only solution, but in most cases, they are like a ball and chain to the user. Because they are so cumbersome, some people won’t wear them all the time they are supposed to. Some people may use the thought: After a couple weeks of exposure they feel ok, they are not noticing any strange health effects, and so it must not be too bad - not giving the long-term effect any thought.

I am sure the loggers in the 1800’s realized after an hour of chopping with the ax the large redwoods would not fall, but after 16-24 hours of chopping what took nature many centuries to grow, man could bring to an end. If man would stop after an hour of chopping the tree, it would keep growing, though it would affect the growth and the external appearance of this mighty tree. Like the mighty redwood tree one little chop at a time over a length of time will bring it down. So, will one breath at a time of contaminated air bring down the mightiest of men?

The round paper mask with one string around the head is only good for nuisance dust. Nuisance dust is dust of large particles only, 10 microns and larger, and the place these can be worn legally is where a dust mask is not really needed. A fitted mask is a mask with a rubber-plastic type seal that fits tight to the face and has an exhaust air valve. This valve will only let air out and none in, so the incoming air must come through the filter.

Anytime air is pulled through a filter the source of suction must work harder than any non-obstructed source would. Thus, in the ole body this is creating a fatigue factor. With the fatigue factor caused by breathing through a filter (dust mask), the level of work performance drops significantly. Testing has shown that while wearing a mask the entire workday, productivity drops 40% in hours six, seven, and eight because every breath of air must be pulled through a filter, resulting in a lower oxygen level and fatigue, and because the person must work hard for EVERY breath of air they take. Put a pencil to paper and the cost of wearing masks verses using an adequate dust collection system becomes clear.

Say the total cost (to the employer) of employing one worker is $10.00 per hour. Losing 40%, costs $4.00 per hour, x three hours per day, equals $12.00 per day x five days per week equals $60.00 per week x 50 weeks per year, which is $3,000.00 that inadequate dust collection has cost you per employee, and you’re making your employees wear dust masks. Yes, I can see the wheels a turning: I can save a lot of money by throwing the darn dust masks away. You are right, until someone working for you becomes ill due to the dust exposure. The only thing that has to be proven is whether you provided a work environment with dust levels exceeding the dust levels allowed by OSHA.

NOW, was it you, or was it the other guy that said dust collection is just an expense, and never provides any income? That is loser mentality thinking; would you rather earn a dollar, or save a dollar? People who understand money will say let your money work hard for you so you don’t work so hard for it. I would much rather save a dollar than earn a dollar, because when you save a dollar you save 100 pennies, but to earn a dollar you must earn between 125-140 pennies and pay 25-40 pennies in various taxes.

Which area of the shop has the most sick leave; which area of the shop has the most help turnover, thus requiring more training? The above numbers (40% productivity drop) were provided to us by a large window manufacture with 60 people sanding windows 10 hours per day.

After they provided adequate dust collection for the sanding department, they said their help turnover and sick leave in the sanding department became the same as the rest of the plant, resulting in huge savings because excessive help turnover and sick leave requires more qualified people to watch new people rather than doing the job they need to be doing. Providing the proper dust collection will pay for itself as fast as or faster than most operating equipment.

A former employee that has been gone less than 24 months can still file a claim against your work-comp for respiratory issues. If you can prove they worked in an environment with dust levels below the maximum allowance, you will most likely win, but if you can’t prove that, it will cost you $$$$$$$$$. Remember: An ounce of prevention is worth a pound of cure.

WHAT IS THE BEST DUST COLLECTION?

The answer is easy: The one that the employees will use and the one that works very well. Everybody is familiar with the central system chip/dust collector. Depending on the size of the shop, a person can spend from 2,500 to a million dollars for such a system. These systems are great to hook up to individual equipment pulling dust created at the source. Source capture is the best type of collection as long as it does not interfere with the worker’s ability to perform the job safely. Capturing dust at the source will prevent dust from traveling into the worker’s breathing zone. OSHA has a rule that states: Never pull the dust up past the workers breathing zone. For best results pull the dust down or back away from the operator. The ceiling mounted or ceiling suspended air cleaners are good for getting rid of air contaminates after they have passed the operator’s breathing zone. In smoke applications, they work well because the smoke rises. In dust applications if overhead collectors are over 12 ft. above the floor they lose most of their effectiveness, and in the case where overhead collectors are used, the best results use the exhaust air (which has been filtered) to push the ambient dirty air towards the next overhead unit. With the use of four big units using the push pull system, they will keep the area in a 40 x 60 ft. room fairly clean. Remember, they are only effective for dust that has passed the operator’s breathing zone. In a long, narrow work area these overheads using the push pull system can keep the area fairly clean. For best results the units need to be approximately 20-30 ft. apart.

The biggest disadvantage to the overhead units is the filters are hard to keep clean in most cases. When the filters get clogged the machine’s performance is reduced substantially, resulting in dirty breathing air. Many of the cheaper models have small filters and they load up very fast, making the investment almost worthless. In the case where ladders must be used to service these units, they seldom get serviced, and there is always danger involved when using ladders.

One last thought on the overhead units:

OUT OF SIGHT, OUT OF MIND.

OUT OF MIND THEY SOON BECOME WORTHLESS.

SOURCE CAPTURE TOOLS

There are some great tools on the market today that are capable of capturing the dust as soon as it is created. Anytime the dust is captured at the point of being created, that becomes the best dust collection. When it is captured at the source this prevents the dust from migrating to the operator’s breathing zone, becoming airborne, and traveling to many unwanted areas. When dust is properly captured at the source, this prevents the 1-50 micron particles dust from floating in the air. These are the sizes you can’t see individually, and can’t see at all unless there is a cloud or a fog of airborne dust. As long as the source capture tools have the filtering capability to capture the dust at 1 micron or greater and the filter has the capacity to do the job without performance loss, this is the least expensive way to go.

There are many great tools on the market that have the vacuum built in so when the tool is turned on the vacuum will turn on also. This feature makes it more user friendly and prevents the vacuum from running when the tool is not in use. There is a great attachment made to hook to your router that when used with a proper vacuum it will virtually capture almost all the router dust. This is an edge routing fixture made to rout on the edge of the products, like counter tops and other large items too large to move the part over the machine. On parts, small enough to handle by hand most jobs can be done on machines that have the dust removed via a central system. Again, this is also source capture because the dust collector captures it as soon as it is made. A lot of jobs are done now on CNC routers; these machines should be equipped with the proper dust collection hoods that will prevent the dust from escaping into the breathing zone of the operator and surrounding workers. Again, get the mind-set of capturing it at the source: it is the best.

Another great advantage built into the portable vacuum source capture systems is that they can be taken to job sites. In the case of working with solid surface on the job site the portable vacuum system can save large amounts of clean up time. They quickly pay for themselves just in clean up time alone, not to mention the obvious advantage of doing a job in an occupied home. The customer will never forget you if you leave them a real fine film of dust all over the inside of their home. Doing a job like this creates word-of mouth advertising no business needs.

Most all these machines come with an adequate filtering system to handle smaller jobs. Sometimes the filter cleaning can be overwhelming, and can cause the person doing the cleaning to be exposed to large amounts of dust that will exceed the maximum limits. NOW the disadvantages to the portable source capture devices is getting the operator to use it all the time. Many shop owners purchase the sanders that are equipped with vacuum ports, and are shocked when the workers say they would rather deal with the dust than work with the cumbersome hoses. Working with a hose a few minutes a day is no big deal, working with one all day can be a problem for some people. OWNERS beware: if you buy them and they don’t use them, and then they acquire a respiratory problem, YOU are still liable. The hoses can slow down some worker’s performance and can prevent a person from doing certain jobs, and they can hang up on different things, which can really be irritating.

When sanding rounded edges many of the sanders are very limited on what they can pick up, because they are designed to have their sanding pad flat on the surface in order to have the proper suction to pick up the dust created. The constant exposure to this real fine dust on some vacuum models has been a real maintenance issue - it is disappointing to purchase a machine with a short operating life, so beware.

Another source capture machine is the downdraft table, these machines, when properly sized for the job, will pull the dust down away from the operator preventing it from getting to the operators breathing zone. These machines have their limitations; in solid surface applications, they work best when working with smaller parts such as vanity tops or smaller furniture pieces. When building kitchens, most fabricators dislike them because of the size and configuration of the tops they work with. They also dislike the downdraft tables because they are hard to fasten their parts to.

To help clean the air when using a downdraft table, there must be enough room around the piece they are working on to have enough downward air movement to pull the dust down into the machine. Most downdraft tables are not equipped to handle routing applications; Denray builds one that is 8 ft. long that can handle large amounts of routing and edge rolling sanding. In any consideration of downdraft tables the filtration must be studied. The filters must be able to capture particles of 1 micron or greater at an efficiency of 99% or better.

With filtration not able to capture down to 1 micron, the dust in the solid surface industry will have what is known as filter blow by. Beware: some companies claim their filter’s capture rate is 1 micron, and it is, but at only 30% efficiency. That means that their filters will not stop 70% of the dust that is 1 micron. Another big item about downdraft tables is the filter cleaning: if filters need to be removed to be cleaned understand that that is more maintenance, and you don’t need more to do, but less. Cartridge filters that are cleaned by the pulsing of compressed air are an industry standard and they are the best filters on the market. They clean down to 0.5 micron at an efficiency of 99.97%.

When working on a downdraft table, smaller pieces will always give you the best results, where the part you are working on will cover no more than 75% of the table’s surface. If more than 75% of the surface is covered, raise the part up to allow the negative air created by the table to go under the part; that will create a much higher air flow resulting in capturing more dust. Because of the extreme variables in shapes of counter tops and fabrication techniques, the benefits of downdraft tables can be limited. Occasionally a custom-built machine may serve your needs if you build a lot of one or two types parts or products.

DUST BOOTHS

In most fabricating applications like solid surface, granite, and the marble industry the dust booth is by far the most efficient and user friendly to work in. OSHA requires the dust to be either pulled down or back away from the operator. The booth is pulling the dust away from the operators, because the dust is falling as it is going towards the power units. Until compressed air is used to blow off the product and stir up dust into the breathing zone, workers are free to work anywhere in the booth in most cases. In large booths, complete kitchens can be fabricated, and done in a completely dust free environment. The one thing everybody does when they are working on jobs like those mentioned above is to blow off the product. Because the booths have sides and an enclosed top the dust stays inside to be sucked into the power units.

Inside the booth, the same work stands the same clamping and the same fabricating techniques you are used to will be the ones you use. The only thing you will learn to work without is the dust. I know for many workers that is part of their well-balanced diet. When working inside of a booth the air coming in needs to be clean, so don’t have someone just outside the booth creating dust. The air movement needs to be in excess of 100 feet per minute inside the booth. As the worker creates dust the heavy chips are going to the floor and the light and all the fine dust will be sucked into the filters. No matter if the person is routing, sanding or grinding, the dust gets replaced with clean air in seconds. In a ten foot deep booth the air is totally replaced in less than 5 seconds. Some people say 10 ft. deep is not deep enough to work in. This is not a problem: most booth fabricators will make them deeper. The beauty of going deeper instead of wider is it functions as a wind tunnel, as long as the dust from the outside worker does not pass the inside worker’s breathing zone. If this design works in your application it is cheaper than going wider as wider requires more CFM of air, which requires more power units, and that costs more money. In some applications, only the power units are needed because the layout of the building will be beneficial in the design of the system. When the room is long and narrow and has a lower ceiling, the system is enhanced. By taking part of the exhaust air and returning it back over the work area (this is called the push-pull system) greater efficiency can be achieved. Depending on the distance, 20-30% of the exhaust will push the ambient dust towards the power units to be filtered. With filtered air pushing the airborne dust towards the power units, widths of 30-40 ft. can be kept clean without being confined inside a work area. With multiple units complete work areas become a very clean work environment.

With part of the exhaust air being piped over the work area, and the remaining pushed into another room this creates a negative air room, causing fresh air to enter through the doors, thus keeping dust from migrating out the doors into other parts of the shop.

The beauty with the booths is that hoses hooked to their tools do not limit workers, and they can rout and sand both in the same area at the same time. They can blow off their products without blowing dust from one part of the shop to the other. They are great at handling multi-sized parts, building complete kitchens today, and sanding hand sized widgets tomorrow.

The filters in the booths need to be the cartridge filters; they need an automatic cleaning system that will keep the filters clean during the use of the machine. The negative to the booths are the initial cost, but it will give a quick return on the investment. Working inside the booths work area may make a person feel claustrophobic with the sides and the ceiling closed in, and the front is the only opening. Some manufactures use heavy clear vinyl allowing light in and the operator to see out - this makes for a friendlier work environment.

CLOSING THOUGHT

Money spent on dust collection is not counterproductive. It is productive and should be considered preventive maintenance. With the huge increase in the cost of the health care, preventing it from happening is cheaper than fixing it. Besides, it may just kill YOU!

Dust particles that are 10 microns in diameter and larger are considered to be large enough to either be caught in the nasal passages, or brought back up out of the upper lungs by cilia. (Cilia are hair like media in the upper lungs and bronchial passages that bring up dust and other foreign matter)

Particles 2.5 micron and smaller are believed to settle in the lower area of the lungs and can’t be brought back up. Once there, they may be dissolved and go into the blood stream to be filtered by the liver, and possibly eliminated from the body. Some of the particles may not be dissolvable and may stay in the lungs, and may cause a variety of problems. (Ex. Allergies, respiratory problems, lung diseases and even cancer). Some of the dust going into the liver may also cause many different medical issues that may or may not be treatable, not to mention incurable.

JUST HOW DUSTY IS YOUR SHOP?

Many of you reading this believe your shop is not all that bad, and some of you may be correct. Some people say we have a serious problem. Those of us in the woodworking industry (including many people reading this) know that OSHA has announced that wood dust is a carcinogen. Many people still debate that ruling and always will. The majority of people that own or operate a shop have little if any idea how much dust is really the maximum limit allowed by OSHA. For most types of wood dust the measurement of 5 mg/m3 is the maximum dust level allowed. Some wood dust has only 3 mg/m3 limits and a few have as low as 1 mg/m3. If you are in the majority, you have no clue what this means.

Some people know that 5 mg/m3 means 5 milligrams of dust per cubic meter. Now some people will say: Just how much is that? NOT MUCH!!! Using flour as a substitute for wood or solid surface dust, I measured out the amount of flour that is the same volume (not weight) as a dime. I weighed the flour in milligrams and converted it to the cubic meter limit allowed by OSHA, 5 mg/m3. If you were to spread the dust evenly into the air and achieve the maximum limits allowed by OSHA, you would need a room 10 ft. x 10 ft. x 8 ft. tall to get a “dime’s worth” of dust to fill the air to the limit. That is at 5 mg/m3.

You say: Who could even see that little amount of dust in normal work environment lights.

You are right: NOW, HOW DUSTY IS YOUR SHOP?

Now, before the panic sets in and a knee-jerk reaction occurs, let’s look at the whole picture. That dust will only be at the maximum level for a few minutes, because it will start to slowly settle below the breathing zone. If more dust is created on an ongoing basis (for instance if someone or several workers were working full time creating dust), then that process and the dust it creates becomes a major concern. The 5 mg/m3 is the maximum limit of full time exposure, so there is some averaging available in these numbers. With spurts of 10 mg/m3 exposure means there needs to be times of basic 0-1 mg/m3 exposure to average at the maximum. (This is known as Time Weighted Averaging, or TWA.)

You may ask: How can we know what our exposure level is? Some work-comp insurance companies will do studies for you, and private safety companies can do testing also. They use a little machine about the size of a big cell phone hooked to your belt all day; this machine will suck air in like a person breathing. At the end of the work period the little monitor will indicate at what level that person was exposed to.

DUST MASK

Are dust masks the answer? Yes, in some cases and NO in most cases. The proper dust mask, and the proper use of them, is 1st: uncomfortable for the person wearing the mask and, 2nd: expensive for the company. In some cases, they are the only solution, but in most cases, they are like a ball and chain to the user. Because they are so cumbersome, some people won’t wear them all the time they are supposed to. Some people may use the thought: After a couple weeks of exposure they feel ok, they are not noticing any strange health effects, and so it must not be too bad - not giving the long-term effect any thought.

I am sure the loggers in the 1800’s realized after an hour of chopping with the ax the large redwoods would not fall, but after 16-24 hours of chopping what took nature many centuries to grow, man could bring to an end. If man would stop after an hour of chopping the tree, it would keep growing, though it would affect the growth and the external appearance of this mighty tree. Like the mighty redwood tree one little chop at a time over a length of time will bring it down. So, will one breath at a time of contaminated air bring down the mightiest of men?

The round paper mask with one string around the head is only good for nuisance dust. Nuisance dust is dust of large particles only, 10 microns and larger, and the place these can be worn legally is where a dust mask is not really needed. A fitted mask is a mask with a rubber-plastic type seal that fits tight to the face and has an exhaust air valve. This valve will only let air out and none in, so the incoming air must come through the filter.

Anytime air is pulled through a filter the source of suction must work harder than any non-obstructed source would. Thus, in the ole body this is creating a fatigue factor. With the fatigue factor caused by breathing through a filter (dust mask), the level of work performance drops significantly. Testing has shown that while wearing a mask the entire workday, productivity drops 40% in hours six, seven, and eight because every breath of air must be pulled through a filter, resulting in a lower oxygen level and fatigue, and because the person must work hard for EVERY breath of air they take. Put a pencil to paper and the cost of wearing masks verses using an adequate dust collection system becomes clear.

Say the total cost (to the employer) of employing one worker is $10.00 per hour. Losing 40%, costs $4.00 per hour, x three hours per day, equals $12.00 per day x five days per week equals $60.00 per week x 50 weeks per year, which is $3,000.00 that inadequate dust collection has cost you per employee, and you’re making your employees wear dust masks. Yes, I can see the wheels a turning: I can save a lot of money by throwing the darn dust masks away. You are right, until someone working for you becomes ill due to the dust exposure. The only thing that has to be proven is whether you provided a work environment with dust levels exceeding the dust levels allowed by OSHA.

NOW, was it you, or was it the other guy that said dust collection is just an expense, and never provides any income? That is loser mentality thinking; would you rather earn a dollar, or save a dollar? People who understand money will say let your money work hard for you so you don’t work so hard for it. I would much rather save a dollar than earn a dollar, because when you save a dollar you save 100 pennies, but to earn a dollar you must earn between 125-140 pennies and pay 25-40 pennies in various taxes.

Which area of the shop has the most sick leave; which area of the shop has the most help turnover, thus requiring more training? The above numbers (40% productivity drop) were provided to us by a large window manufacture with 60 people sanding windows 10 hours per day.

After they provided adequate dust collection for the sanding department, they said their help turnover and sick leave in the sanding department became the same as the rest of the plant, resulting in huge savings because excessive help turnover and sick leave requires more qualified people to watch new people rather than doing the job they need to be doing. Providing the proper dust collection will pay for itself as fast as or faster than most operating equipment.

A former employee that has been gone less than 24 months can still file a claim against your work-comp for respiratory issues. If you can prove they worked in an environment with dust levels below the maximum allowance, you will most likely win, but if you can’t prove that, it will cost you $$$$$$$$$. Remember: An ounce of prevention is worth a pound of cure.

WHAT IS THE BEST DUST COLLECTION?

The answer is easy: The one that the employees will use and the one that works very well. Everybody is familiar with the central system chip/dust collector. Depending on the size of the shop, a person can spend from 2,500 to a million dollars for such a system. These systems are great to hook up to individual equipment pulling dust created at the source. Source capture is the best type of collection as long as it does not interfere with the worker’s ability to perform the job safely. Capturing dust at the source will prevent dust from traveling into the worker’s breathing zone. OSHA has a rule that states: Never pull the dust up past the workers breathing zone. For best results pull the dust down or back away from the operator. The ceiling mounted or ceiling suspended air cleaners are good for getting rid of air contaminates after they have passed the operator’s breathing zone. In smoke applications, they work well because the smoke rises. In dust applications if overhead collectors are over 12 ft. above the floor they lose most of their effectiveness, and in the case where overhead collectors are used, the best results use the exhaust air (which has been filtered) to push the ambient dirty air towards the next overhead unit. With the use of four big units using the push pull system, they will keep the area in a 40 x 60 ft. room fairly clean. Remember, they are only effective for dust that has passed the operator’s breathing zone. In a long, narrow work area these overheads using the push pull system can keep the area fairly clean. For best results the units need to be approximately 20-30 ft. apart.

The biggest disadvantage to the overhead units is the filters are hard to keep clean in most cases. When the filters get clogged the machine’s performance is reduced substantially, resulting in dirty breathing air. Many of the cheaper models have small filters and they load up very fast, making the investment almost worthless. In the case where ladders must be used to service these units, they seldom get serviced, and there is always danger involved when using ladders.

One last thought on the overhead units:

OUT OF SIGHT, OUT OF MIND.

OUT OF MIND THEY SOON BECOME WORTHLESS.

SOURCE CAPTURE TOOLS

There are some great tools on the market today that are capable of capturing the dust as soon as it is created. Anytime the dust is captured at the point of being created, that becomes the best dust collection. When it is captured at the source this prevents the dust from migrating to the operator’s breathing zone, becoming airborne, and traveling to many unwanted areas. When dust is properly captured at the source, this prevents the 1-50 micron particles dust from floating in the air. These are the sizes you can’t see individually, and can’t see at all unless there is a cloud or a fog of airborne dust. As long as the source capture tools have the filtering capability to capture the dust at 1 micron or greater and the filter has the capacity to do the job without performance loss, this is the least expensive way to go.

There are many great tools on the market that have the vacuum built in so when the tool is turned on the vacuum will turn on also. This feature makes it more user friendly and prevents the vacuum from running when the tool is not in use. There is a great attachment made to hook to your router that when used with a proper vacuum it will virtually capture almost all the router dust. This is an edge routing fixture made to rout on the edge of the products, like counter tops and other large items too large to move the part over the machine. On parts, small enough to handle by hand most jobs can be done on machines that have the dust removed via a central system. Again, this is also source capture because the dust collector captures it as soon as it is made. A lot of jobs are done now on CNC routers; these machines should be equipped with the proper dust collection hoods that will prevent the dust from escaping into the breathing zone of the operator and surrounding workers. Again, get the mind-set of capturing it at the source: it is the best.

Another great advantage built into the portable vacuum source capture systems is that they can be taken to job sites. In the case of working with solid surface on the job site the portable vacuum system can save large amounts of clean up time. They quickly pay for themselves just in clean up time alone, not to mention the obvious advantage of doing a job in an occupied home. The customer will never forget you if you leave them a real fine film of dust all over the inside of their home. Doing a job like this creates word-of mouth advertising no business needs.

Most all these machines come with an adequate filtering system to handle smaller jobs. Sometimes the filter cleaning can be overwhelming, and can cause the person doing the cleaning to be exposed to large amounts of dust that will exceed the maximum limits. NOW the disadvantages to the portable source capture devices is getting the operator to use it all the time. Many shop owners purchase the sanders that are equipped with vacuum ports, and are shocked when the workers say they would rather deal with the dust than work with the cumbersome hoses. Working with a hose a few minutes a day is no big deal, working with one all day can be a problem for some people. OWNERS beware: if you buy them and they don’t use them, and then they acquire a respiratory problem, YOU are still liable. The hoses can slow down some worker’s performance and can prevent a person from doing certain jobs, and they can hang up on different things, which can really be irritating.

When sanding rounded edges many of the sanders are very limited on what they can pick up, because they are designed to have their sanding pad flat on the surface in order to have the proper suction to pick up the dust created. The constant exposure to this real fine dust on some vacuum models has been a real maintenance issue - it is disappointing to purchase a machine with a short operating life, so beware.

Another source capture machine is the downdraft table, these machines, when properly sized for the job, will pull the dust down away from the operator preventing it from getting to the operators breathing zone. These machines have their limitations; in solid surface applications, they work best when working with smaller parts such as vanity tops or smaller furniture pieces. When building kitchens, most fabricators dislike them because of the size and configuration of the tops they work with. They also dislike the downdraft tables because they are hard to fasten their parts to.

To help clean the air when using a downdraft table, there must be enough room around the piece they are working on to have enough downward air movement to pull the dust down into the machine. Most downdraft tables are not equipped to handle routing applications; Denray builds one that is 8 ft. long that can handle large amounts of routing and edge rolling sanding. In any consideration of downdraft tables the filtration must be studied. The filters must be able to capture particles of 1 micron or greater at an efficiency of 99% or better.

With filtration not able to capture down to 1 micron, the dust in the solid surface industry will have what is known as filter blow by. Beware: some companies claim their filter’s capture rate is 1 micron, and it is, but at only 30% efficiency. That means that their filters will not stop 70% of the dust that is 1 micron. Another big item about downdraft tables is the filter cleaning: if filters need to be removed to be cleaned understand that that is more maintenance, and you don’t need more to do, but less. Cartridge filters that are cleaned by the pulsing of compressed air are an industry standard and they are the best filters on the market. They clean down to 0.5 micron at an efficiency of 99.97%.

When working on a downdraft table, smaller pieces will always give you the best results, where the part you are working on will cover no more than 75% of the table’s surface. If more than 75% of the surface is covered, raise the part up to allow the negative air created by the table to go under the part; that will create a much higher air flow resulting in capturing more dust. Because of the extreme variables in shapes of counter tops and fabrication techniques, the benefits of downdraft tables can be limited. Occasionally a custom-built machine may serve your needs if you build a lot of one or two types parts or products.

DUST BOOTHS

In most fabricating applications like solid surface, granite, and the marble industry the dust booth is by far the most efficient and user friendly to work in. OSHA requires the dust to be either pulled down or back away from the operator. The booth is pulling the dust away from the operators, because the dust is falling as it is going towards the power units. Until compressed air is used to blow off the product and stir up dust into the breathing zone, workers are free to work anywhere in the booth in most cases. In large booths, complete kitchens can be fabricated, and done in a completely dust free environment. The one thing everybody does when they are working on jobs like those mentioned above is to blow off the product. Because the booths have sides and an enclosed top the dust stays inside to be sucked into the power units.

Inside the booth, the same work stands the same clamping and the same fabricating techniques you are used to will be the ones you use. The only thing you will learn to work without is the dust. I know for many workers that is part of their well-balanced diet. When working inside of a booth the air coming in needs to be clean, so don’t have someone just outside the booth creating dust. The air movement needs to be in excess of 100 feet per minute inside the booth. As the worker creates dust the heavy chips are going to the floor and the light and all the fine dust will be sucked into the filters. No matter if the person is routing, sanding or grinding, the dust gets replaced with clean air in seconds. In a ten foot deep booth the air is totally replaced in less than 5 seconds. Some people say 10 ft. deep is not deep enough to work in. This is not a problem: most booth fabricators will make them deeper. The beauty of going deeper instead of wider is it functions as a wind tunnel, as long as the dust from the outside worker does not pass the inside worker’s breathing zone. If this design works in your application it is cheaper than going wider as wider requires more CFM of air, which requires more power units, and that costs more money. In some applications, only the power units are needed because the layout of the building will be beneficial in the design of the system. When the room is long and narrow and has a lower ceiling, the system is enhanced. By taking part of the exhaust air and returning it back over the work area (this is called the push-pull system) greater efficiency can be achieved. Depending on the distance, 20-30% of the exhaust will push the ambient dust towards the power units to be filtered. With filtered air pushing the airborne dust towards the power units, widths of 30-40 ft. can be kept clean without being confined inside a work area. With multiple units complete work areas become a very clean work environment.

With part of the exhaust air being piped over the work area, and the remaining pushed into another room this creates a negative air room, causing fresh air to enter through the doors, thus keeping dust from migrating out the doors into other parts of the shop.

The beauty with the booths is that hoses hooked to their tools do not limit workers, and they can rout and sand both in the same area at the same time. They can blow off their products without blowing dust from one part of the shop to the other. They are great at handling multi-sized parts, building complete kitchens today, and sanding hand sized widgets tomorrow.

The filters in the booths need to be the cartridge filters; they need an automatic cleaning system that will keep the filters clean during the use of the machine. The negative to the booths are the initial cost, but it will give a quick return on the investment. Working inside the booths work area may make a person feel claustrophobic with the sides and the ceiling closed in, and the front is the only opening. Some manufactures use heavy clear vinyl allowing light in and the operator to see out - this makes for a friendlier work environment.

CLOSING THOUGHT

Money spent on dust collection is not counterproductive. It is productive and should be considered preventive maintenance. With the huge increase in the cost of the health care, preventing it from happening is cheaper than fixing it. Besides, it may just kill YOU!